This is an updated version of the article originally published in the Journal of the Society of American Bayonet Collectors

Ever since the bayonet was ‘invented’, numerous innovations have been attempted over the years to render them more useful by combining functions. Thus 'sword bayonets', 'sawback bayonets', 'flint knappers' and so on.

Perhaps the most exotic and impractical innovation developed during the Great War : the ‘Wire-Breaker’.

During the course of WWI, thousands of barbed wire obstacles were installed by opposing sides to protect against advancing infantry. Penetrating these ideal defensive barricades became a major pre-occupation on the Western Front.

Artillery barrages were used to clear barbed wire entanglements prior to massed infantry assault, but by pock-marking the ground with shell holes, it only compounded the difficulties of advance. Ultimately, the newly developed ‘tank’ proved the ideal solution, able to flatten wire and provide effective cover for troops as they advanced behind them.

The concept of a bayonet mounted wire-breaker was simple enough. As the soldier advanced through fields of barbed wire and machinegun fire towards the enemy trenches, it was supposed he would possess a sufficiently level head, and have enough time to ‘break’ through stands of wire individually. To accomplish this he simply had to slide a strand of wire along the bayonet blade until it came to rest in the notch of his Wire-Breaker. In doing so, it was automatically aligned with the muzzle of the rifle. Theoretically, firing a round would be sufficient to break the strand, allowing him to proceed with his advance.

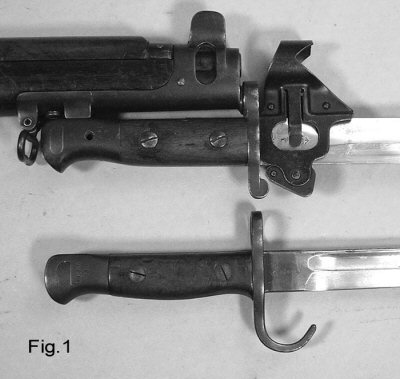

The illustrated Wire Breaker No 1 was approved on 9th May 1912 the British War Department in anticipation of the needs to come.

Manufactured from sheet steel, the wire-breaker was designed to slide along the bayonet blade until it rested against the crossguard. A built-in spring clip held it in place.

British Imperial forces were likely to find they could either be fixing Pattern 1903 or 1907 bayonets to their SMLE Rifles. The blade width of a P1903 bayonet is 30mm, a P1907 bayonet only 23mm.

To render the Wire Breaker universal to both bayonets, a swiveling wedge was built into the bottom, providing a snug fit against either blade when moved to the appropriate position.

To help the soldier determine the correct position of the wedge during the heat of battle, the numbers ‘3’ and ‘7’ were stamped into the opposite sides of the body and swivel of the Breaker, corresponding to the pattern of bayonet in use. Matching the two numbers meant the Breaker was in the correct position to fit either the P1903 or P1907 bayonet.

Five further patterns were approved, including one to fit the P1913 bayonet, and all were finally declared obsolete in February of 1921.

Lost, destroyed or recycled over the years, these mass produced ‘penny’ items are now extraordinarily hard to find, and highly desirable to the bayonet collector.

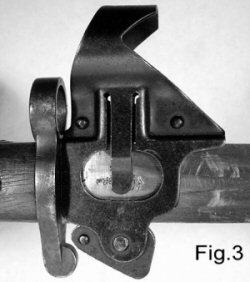

The innovation was further developed by the Wilkinson Sword company, incorporating the wire-breaker into the crossguard itself.

The ‘catcher’ resting on the back of the blade swivels upwards to provide sufficient clearance for the bayonet to fit into the scabbard.

The crossguard must have been an extraordinarily difficult casting to make, and prone to catching in clothing and equipment when sheathed. Never adopted by the War Department, it is probable that only a handful were made. I know of only one other outside of my own collection.

Like so many bright ideas borne of the times, it is probable that the inventor of the wire-breaker never actually had to apply his idea in practice. One can only imagine the futility of attempting to break through barbed entanglements using this method whilst under enemy fire.